Sale!

Description

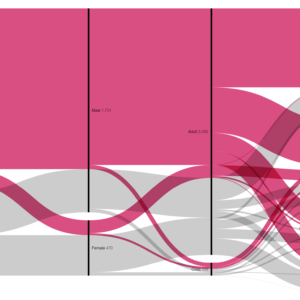

A centerline labeling chart is a graphical tool that shows the variation of a process over time, using a centerline as a reference point. The centerline represents the average or target value of the process, and the data points are plotted around it. The chart can also include upper and lower control limits, which indicate the acceptable range of variation for the process.

Purposes :

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.