Sale!

Description

Description :

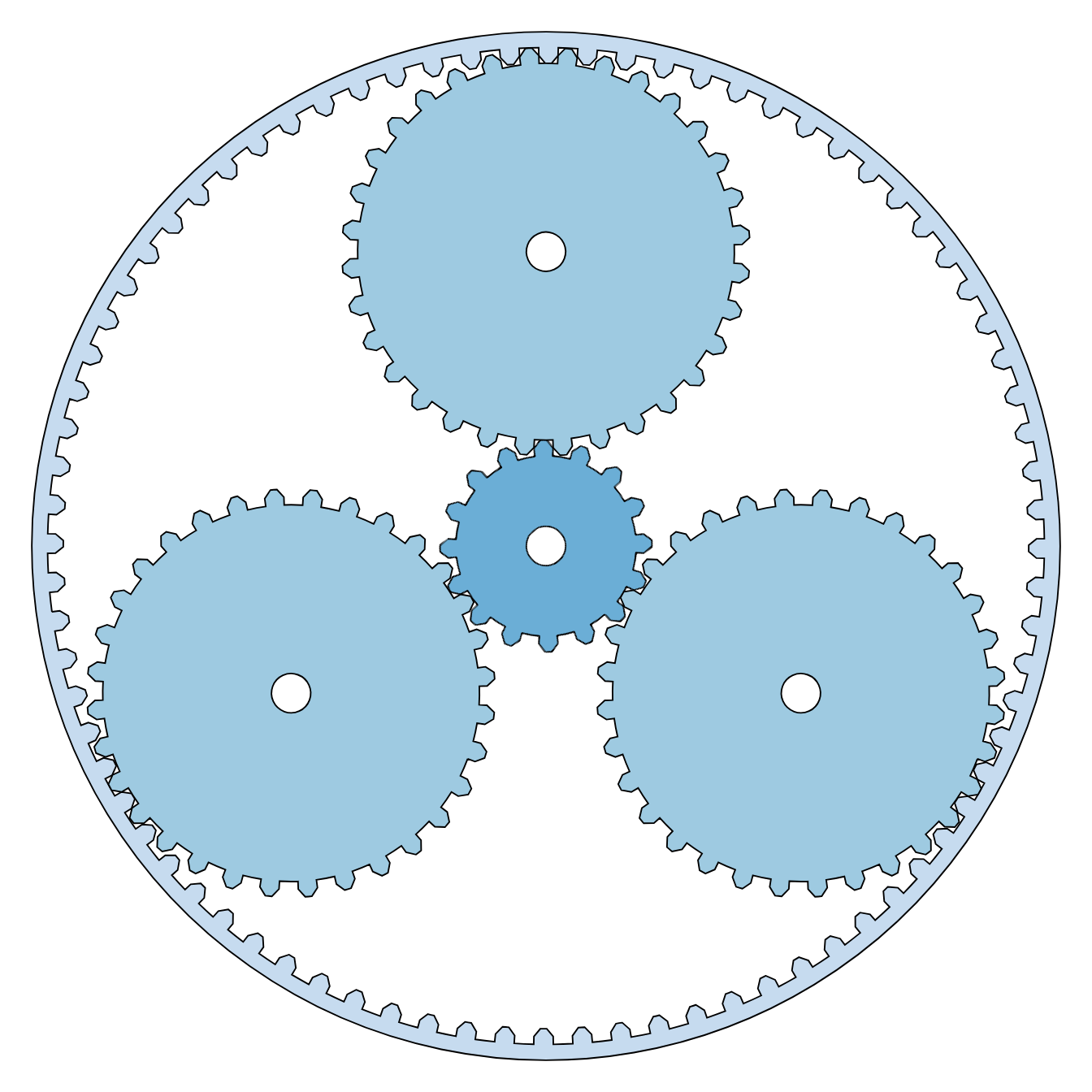

Epicyclic gearing, also known as planetary gearing, is a gear mechanism that consists of a central gear (sun gear), surrounded by multiple smaller gears (planet gears), all of which rotate within a larger ring gear (annulus). This configuration allows for compact and versatile transmission systems, commonly used in applications such as automotive transmissions and precision machinery.

Purposes :

Uses :

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.